At PacMastery, our mission is to revolutionize the packing machinery industry through innovative solutions, unparalleled quality, and relentless dedication to customer satisfaction. We strive to empower businesses around the globe with cutting-edge technology and customized machinery, ensuring efficiency, reliability, and excellence in every packaging process. Committed to sustainability and ethical practices, we are not just building machines; we’re crafting a more efficient, productive, and responsible future in packaging.

Key Takeaways

| Aspect | Details |

|---|---|

| Types of Machines | Automatic and semi-automatic atta packing machines |

| Key Features | Packaging speed, power consumption, automation grade, customization options |

| Common Challenges | Manual packaging challenges, need for skilled workers, consistency issues |

| Choosing the Right Machine | Assess production volume, type of flour, budget, and specific needs |

| Industry Standards | Compliance with safety and quality standards, benefits of certified machines |

| Expert Advice | Recommendations on machine maintenance, efficiency improvements, and scalability |

Introduction

Atta packing machines are essential in the food packaging industry, especially with the growing demand for efficient and consistent packaging solutions. These machines play a critical role in ensuring that atta, a staple in many households, is packaged accurately and securely. As consumer habits evolve and the demand for packaged atta increases, understanding the features, benefits, and selection criteria for atta packing machines becomes crucial for businesses.

Types of Atta Packing Machines

Automatic Atta Packing Machines

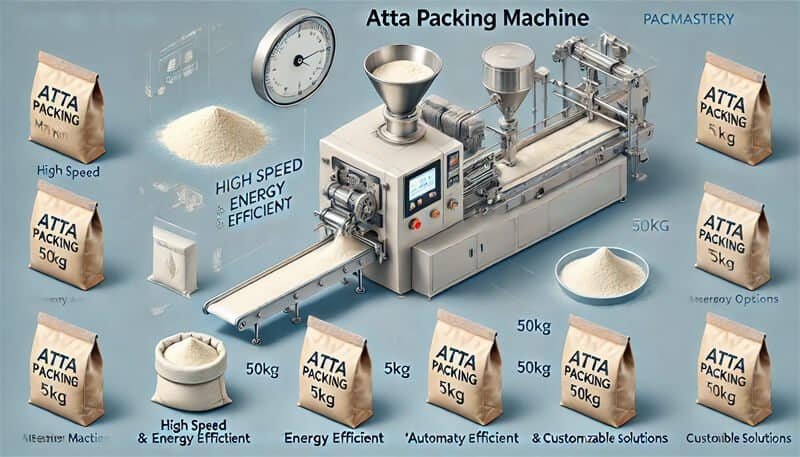

Automatic atta packing machines are designed to streamline the packaging process with minimal human intervention. These machines are ideal for large-scale operations where speed and consistency are paramount.

- Features: High speed, automation, minimal human intervention.

- Benefits: Increased productivity, and consistent packaging quality.

- Examples: Machines capable of handling different bag sizes and types, from small 500g packs to large 50kg sacks.

Semi-Automatic Atta Packing Machines

Semi-automatic atta packing machines require some level of manual input but are generally more affordable and flexible for smaller operations.

- Features: Requires some manual intervention, generally lower cost.

- Benefits: Suitable for smaller operations, flexible for different packaging needs.

- Examples: Easy-to-operate machines that are cost-effective and maintainable.

Key Features to Look For

Packaging Speed

Packaging speed is a critical factor that influences productivity. Machines with higher speeds can handle more packages per minute, making them suitable for high-volume operations.

- Example: Competitors offer machines with speeds ranging from 5 to 70 bags per minute.

Power Consumption

Energy efficiency is important for reducing long-term operational costs. Choosing a machine with optimal power consumption ensures cost savings and environmental benefits.

- Example: Machines with power consumption ranging from 250W to 8KW.

Automation Grade

Understanding the level of automation required for your operation is essential. Fully automatic machines offer higher productivity with less manual intervention, while semi-automatic machines provide flexibility at a lower cost.

Customization Options

Customization options allow businesses to tailor their machines to specific needs, such as different types of flour and various bag sizes and types.

- Examples: Machines capable of packaging different types of flour (wheat, rice, gram) in diverse bag sizes (500g to 50kg).

Challenges and Solutions

Manual Packaging Challenges

Manual packaging often presents challenges such as the need for skilled workers, inconsistency, and potential for human error. These issues can lead to inefficiencies and higher operational costs.

Solutions with Automatic Machines

Automatic machines address these challenges by providing consistent and accurate packaging. Features like touch screen settings, PLC control, and easy weight adjustments enhance efficiency and reduce reliance on skilled labor.

- Example: Competitor machines with touch screen settings for weight adjustments and PLC control systems.

Choosing the Right Machine

Assessing Your Needs

When choosing an atta packing machine, it's important to consider factors such as production volume, type of flour, and budget. These factors will help determine the most suitable machine for your operation.

Evaluating Machine Specifications

Pay attention to technical specifications like voltage, packaging speed, and accuracy. These specs are crucial for ensuring that the machine meets your operational requirements.

- Example: Machines with specifications like 440V voltage, accuracy of 0.5%-0.7%, and various automation levels.

Industry Norms and Certifications

Ensure that the machine complies with industry standards and certifications. Certified machines offer reliability, safety, and long service life.

- Benefits: Long service life, reliable performance, compliance with safety and quality standards.

Expert Advice and Industry Norms

Expert Recommendations

When selecting an atta packing machine, expert recommendations can provide valuable insights into the features and capabilities that best suit your business needs. Industry professionals often emphasize the importance of maintenance, efficiency improvements, and scalability.

- Maintenance: Regular maintenance ensures the longevity and reliability of the machines. Experts suggest routine checks and timely servicing to avoid unexpected downtimes.

- Efficiency Improvements: Incorporating advanced features like touch screen settings and PLC controls can significantly enhance operational efficiency. These features allow for quick adjustments and real-time monitoring.

- Scalability: As your business grows, the need for scalable solutions becomes evident. Machines that offer modular upgrades and higher capacities can accommodate increased production demands.

Adhering to Industry Norms

Compliance with industry standards and certifications is crucial for ensuring the safety, quality, and reliability of your atta packing machines. Certified machines not only meet regulatory requirements but also provide peace of mind with their guaranteed performance.

- Safety Standards: Ensure that the machines comply with safety standards to protect operators and maintain a safe working environment.

- Quality Standards: High-quality machines adhere to industry benchmarks for performance and durability, ensuring consistent packaging results.

- Environmental Standards: Choosing energy-efficient machines that meet environmental standards contributes to sustainability and reduces operational costs.

Conclusion

In summary, atta packing machines are essential for efficient and consistent packaging in the food industry. By understanding the different types of machines, key features, challenges, and solutions, businesses can make informed decisions to optimize their packaging processes.

Key Points

- Types of Machines: Automatic and semi-automatic machines cater to different operational needs.

- Key Features: Packaging speed, power consumption, automation grade, and customization options are critical for optimal performance.

- Challenges and Solutions: Addressing manual packaging challenges with advanced automatic machines improves efficiency and consistency.

- Choosing the Right Machine: Assessing production volume, type of flour, and budget helps in selecting the most suitable machine.

- Expert Advice and Industry Norms: Following expert recommendations and adhering to industry standards ensure reliable and efficient packaging operations.

Explore our other innovative packaging solutions to enhance your production efficiency:

- Granule Packing Machine Factory

- Liquid Packing Machine Supplier

- Powder Packing Machine Manufacturer

- Innovative Solutions for K-Cup Packaging

- Revolutionizing Cannabis Packaging Automation

PacMastery is dedicated to providing top-notch, customized packaging solutions to meet the diverse needs of businesses around the globe. Join us in revolutionizing the packaging industry with cutting-edge technology and unparalleled customer service. Visit PacMastery to learn more about our mission and values.