Key Takeaways

| Question | Answer |

|---|---|

| What is a small sachet packing machine? | A machine designed to fill and seal small sachets with various products such as powders, granules, or liquids. |

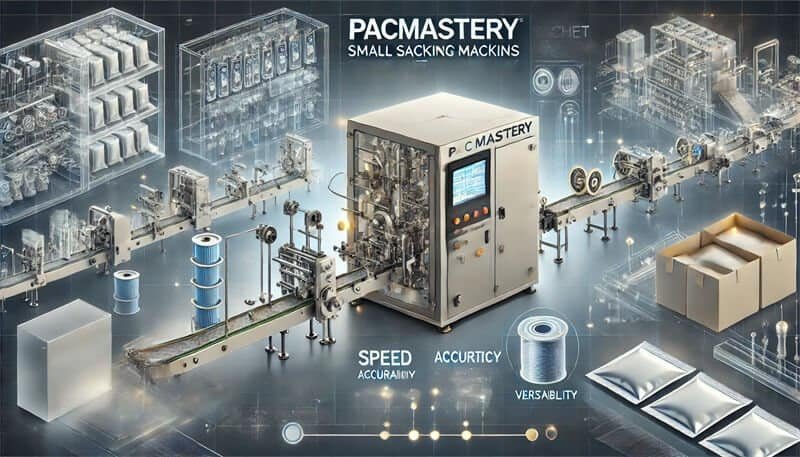

| What are the key features? | Speed, accuracy, versatility, and the ability to handle various packaging materials. |

| Why is it important? | Essential for efficient, reliable, and high-quality packaging in industries like food, pharmaceuticals, and chemicals. |

| How to choose the right machine? | Consider production needs, budget, customization options, and expert advice. |

| What components are crucial? | High-quality components like Schneider/Siemens for reliability and performance. |

Introduction

At PacMastery, our mission is to revolutionize the packing machinery industry through innovative solutions, unparalleled quality, and relentless dedication to customer satisfaction. We strive to empower businesses around the globe with cutting-edge technology and customized machinery, ensuring efficiency, reliability, and excellence in every packaging process. Committed to sustainability and ethical practices, we are not just building machines; we’re crafting a more efficient, productive, and responsible future in packaging.

What is a Small Sachet Packing Machine?

A small sachet packing machine is a specialized device designed to fill and seal small sachets with a variety of products, including powders, granules, and liquids. These machines are crucial in industries like food, pharmaceuticals, and chemicals where precise, efficient, and reliable packaging is essential.

Key Features of Small Sachet Packing Machines

Speed and Efficiency

- High Packaging Speed: Capable of packing up to 80 bags per minute, these machines significantly enhance production efficiency.

- Automation Levels: Available in both semi-automatic and fully automatic models, allowing businesses to choose based on their specific needs and budget.

Accuracy and Precision

- High Accuracy: Ensuring packaging accuracy of ±0.3-1% depending on the weight and material, these machines minimize product wastage and ensure consistency.

- Advanced Sealing: Precise sealing mechanisms ensure the integrity of the packaging, maintaining product quality and safety.

Versatility and Adaptability

- Material Compatibility: Suitable for various packaging materials, including composite films and plastics, providing flexibility in packaging options.

- Multiple Bag Types: Supports different bag styles such as pillow bags, side-gusset bags, and daypacks, catering to diverse packaging needs.

Detailed Technical Specifications

Understanding the technical specifications of small sachet packing machines is crucial for making informed purchasing decisions. Here are some common specs to consider:

- Size and Dimensions: Varies based on machine model; typically ranges from compact designs to larger industrial setups.

- Weight: Can range from 1200 kg to 1600 kg depending on the machine's capacity and features.

- Power Requirements: Standard models operate on 220V or 380V, ensuring compatibility with industrial power supplies.

Example Specifications from Top Competitors

Elinpack

- Packaging Speed: Up to 80 bags/minute

- Packaging Accuracy: ±0.3-1%

- Compatible Materials: Composite films, plastic

Acepack S-180Z

- Production Capacity: 40-80 bags/minute

- Automation Level: Full-automatic

- Key Components: Schneider/Siemens

KLS Double Chamber

- Production Capacity: 6 bags/minute

- Automation Level: Semi-automatic

- Application: Food packing

Industry Applications

Food and Beverage

Small sachet packing machines are extensively used in the food and beverage industry for packaging products such as snacks, powders, and liquids. These machines ensure that the packaging process is hygienic, efficient, and meets industry standards.

Chemicals and Pharmaceuticals

In the chemical and pharmaceutical industries, precision and safety are paramount. Small sachet packing machines provide the accuracy required for these sensitive products, ensuring that each sachet is filled correctly and sealed securely.

Advantages of Using High-Quality Components

Using high-quality components like those from Schneider and Siemens enhances the reliability and performance of small sachet packing machines. These components contribute to the machine's longevity, reduce maintenance needs, and ensure consistent operation.

Expert Tips on Maintenance

Regular maintenance is key to the optimal performance of packing machines. Here are some tips:

- Routine Inspections: Regularly check for wear and tear.

- Component Replacement: Replace any worn-out parts promptly.

- Professional Servicing: Schedule periodic professional servicing to keep the machine in top condition.

Comparison of Top Small Sachet Packing Machines

To help you make an informed decision, we have compared the top small sachet packing machines available on the market. Below is a comparison of Elinpack, Acepack S-180Z, and KLS Double Chamber machines:

| Feature | Elinpack | Acepack S-180Z | KLS Double Chamber |

|---|---|---|---|

| Packaging Speed | Up to 80 bags/min | 40-80 bags/min | 6 bags/min |

| Packaging Accuracy | ±0.3-1% | ±0.3-1% | ±0.5% |

| Automation Level | Full-automatic | Full-automatic | Semi-automatic |

| Materials Supported | Composite films, plastic | Doypack, pouch packing | Plastic |

| Key Components | Schneider/Siemens | Schneider/Siemens | PLC |

| Application | Food, chemicals, pharmaceuticals | Food, beverages, chemicals | Food packing |

| Dimensions | Varies by model | 4650x970x1500 mm | 1050x650x855 mm |

| Weight | 1600 kg | 1400 kg | 1200 kg |

| Power Requirements | 220V/380V | 220V/380V | 380V |

Buying Guide: How to Choose the Right Small Sachet Packing Machine

Selecting the right small sachet packing machine can be daunting, but focusing on key factors can simplify the process. Here’s what to consider:

Factors to Consider

- Production Needs and Capacity: Assess your daily production requirements and choose a machine that can meet or exceed this demand.

- Budget and Cost Considerations: Determine your budget, including initial investment and ongoing maintenance costs. Balance cost with the machine’s features and benefits.

- Customization and Flexibility Options: Ensure the machine can handle various packaging materials and bag types to meet your diverse needs.

Expert Tips

- Consult Industry Experts: Seek advice from industry professionals to understand the best machine for your specific application.

- Visit Trade Shows: Attending trade shows can provide hands-on experience with different machines and direct interaction with manufacturers.

- Request Demos and Trials: If possible, request a demo or trial period to test the machine’s performance in real-world conditions.

Conclusion

Small sachet packing machines are an indispensable asset for businesses in various industries. They offer speed, accuracy, and versatility, ensuring efficient and high-quality packaging. By considering key features, understanding technical specifications, and following expert tips, you can select the best machine to enhance your packaging process.

At PacMastery, we are committed to providing innovative, high-quality packaging solutions that empower businesses worldwide. Explore our range of small sachet packing machines and discover how we can help you revolutionize your packaging efficiency and reliability.

FAQs

What types of products can small sachet packing machines handle? Small sachet packing machines can handle a variety of products, including powders, granules, liquids, and semi-solids. They are commonly used in the food, pharmaceutical, and chemical industries.

How do I maintain my small sachet packing machine? Regular maintenance includes routine inspections, replacing worn-out parts, and scheduling professional servicing. This ensures the machine operates efficiently and prolongs its lifespan.

What is the difference between semi-automatic and fully automatic sachet packing machines? Semi-automatic machines require some manual intervention during the packaging process, whereas fully automatic machines handle the entire process from filling to sealing without manual input, offering higher efficiency and consistency.

Can these machines be customized? Yes, many manufacturers offer customization options to meet specific packaging needs, including adjustments for different bag types, sizes, and materials.

Why are high-quality components important in these machines? High-quality components, such as those from Schneider and Siemens, ensure the machine’s reliability, performance, and longevity, reducing downtime and maintenance costs.

Discover more about our innovative packaging solutions and how they can transform your business at PacMastery.

By leveraging advanced technology and our dedication to customer satisfaction, PacMastery is your trusted partner in achieving excellence in packaging. Visit our website to learn more about our innovative solutions and how we can help you stay ahead in the competitive packaging industry.