At PacMastery, our mission is to revolutionize the packing machinery industry through innovative solutions, unparalleled quality, and relentless dedication to customer satisfaction. We strive to empower businesses around the globe with cutting-edge technology and customized machinery, ensuring efficiency, reliability, and excellence in every packaging process. Committed to sustainability and ethical practices, we are not just building machines; we’re crafting a more efficient, productive, and responsible future in packaging.

Key Takeaways

| Aspect | Details |

|---|---|

| High Efficiency | Speeds of 500-800 pcs/min, reduced labor costs, consistent quality. |

| Cost Savings | Automation reduces labor costs, energy-efficient operations lower utility expenses. |

| Improved Hygiene | Minimizes human contact, ensuring high hygiene standards. |

| Technical Specifications | Customizable dimensions, various sizes (NB, S, M, L, XL, XXL), full-servo systems. |

| Unique Features | Innovative gusset-making, short packaging length, full-servo control, ultrasonic welding. |

| Customer Testimonials | Positive feedback highlighting reliability, quality, and performance. |

| Market Trends | Rising demand for disposable diapers, focus on sustainability, integration of smart technologies. |

Introduction

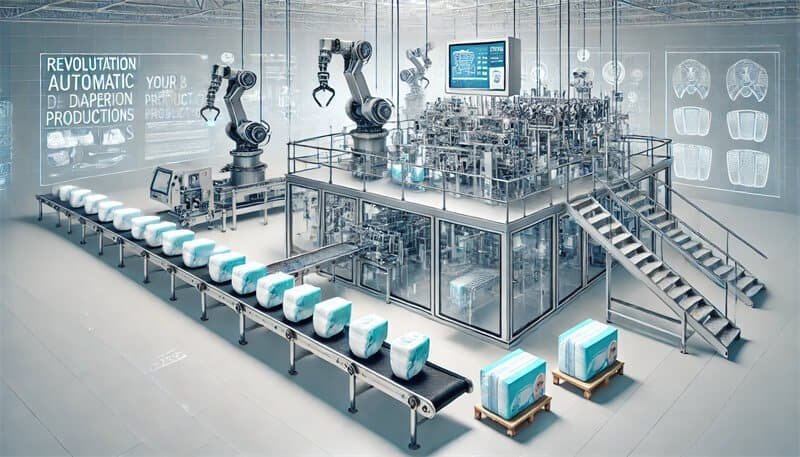

In the rapidly evolving world of diaper manufacturing, efficiency and reliability are paramount. At PacMastery, we understand the challenges faced by manufacturers and offer state-of-the-art fully automatic baby diaper packing machines designed to revolutionize the production process. These machines not only enhance productivity but also ensure superior hygiene standards and significant cost savings.

Benefits of Fully Automatic Baby Diaper Packing Machines

High Efficiency

Our fully automatic baby diaper packing machines operate at impressive speeds, typically ranging from 500 to 800 pieces per minute. This high-speed operation significantly boosts productivity, allowing manufacturers to meet increasing market demands with ease. Moreover, the automation of the packing process ensures consistent quality control, minimizing defects and ensuring that each diaper meets stringent standards.

Cost Savings

By automating the packing process, labor costs are drastically reduced. Fewer workers are needed to operate and oversee the machines, leading to significant savings in wages and associated expenses. Additionally, our machines are designed to be energy efficient, utilizing full-servo systems that consume less power compared to traditional mechanical systems. This reduction in energy consumption translates to lower utility bills and a smaller carbon footprint.

Improved Hygiene

Hygiene is a critical concern in diaper manufacturing. Our fully automatic machines minimize human contact with the diapers, significantly reducing the risk of contamination. The automated process ensures that each diaper is packed in a sterile environment, maintaining high hygiene standards and complying with industry regulations.

Key Components of Fully Automatic Baby Diaper Packing Machines

Raw Material Feeding System

The raw material feeding system ensures a continuous supply of essential materials, such as non-woven fabrics, fluff pulp, and adhesive tapes. This system is designed to handle large rolls of material, preparing them for the diaper-forming process without interruption.

Diaper Forming Unit

The diaper forming unit is where the magic happens. This unit folds and assembles the various components of the diaper, including the absorbent core, back sheet, and frontal tape. The precise and efficient operation of this unit is crucial for producing high-quality diapers consistently.

Ultrasonic Welding System

Ultrasonic welding technology is used to securely bond the different components of the diaper. This method ensures leak-proof seals and enhances the durability of the diapers. Ultrasonic welding is faster and more reliable than traditional adhesive methods, contributing to the overall efficiency of the production process.

Cutting and Packaging System

Once the diapers are formed, the cutting and packaging system takes over. This system precisely cuts the formed diapers into individual pieces and hygienically packages them, ready for distribution. The accuracy and speed of this system are essential for maintaining high production rates and ensuring that the final product meets quality standards.

Technical Specifications and Unique Features

Speed and Capacity

Our machines offer varying speeds and capacities to meet the diverse needs of our clients. With speeds ranging from 500 to 800 pieces per minute and power capacities between 280 to 330KW, our machines are built to handle large-scale production efficiently.

Customization Options

We understand that different markets have different requirements. That's why our machines are customizable to produce diapers in various sizes, including NB, S, M, L, XL, and XXL. This flexibility allows manufacturers to cater to a wide range of consumer preferences.

Energy Efficiency

Utilizing full-servo systems, our machines are designed to be more energy-efficient than traditional mechanical systems. This not only reduces operational costs but also supports our commitment to sustainability and ethical practices.

Innovative Features

Our fully automatic baby diaper packing machines come equipped with several innovative features:

- Gusset-Making Mechanism: This mechanism ensures minimal misalignment and error, enhancing the stability and quality of the packaging.

- Short Packaging Length Requirement: By adopting unique production technology, our machines can operate with a shorter packaging length, significantly reducing material costs.

- Full-Servo Control: This advanced control system offers more stable operation, accurate positioning, and lower energy consumption compared to traditional methods.

Customer Testimonials and Success Stories

Building Trust with Customers

Our commitment to quality and customer satisfaction is reflected in the positive feedback we receive from our clients. Here are some testimonials from satisfied customers who have experienced the benefits of our fully automatic baby diaper packing machines:

- "I am very happy with the machinery we are going to buy; this is a start for business relations with PacMastery." - Sergio

- "Before four years, we ordered the first full waistband baby diaper production line from PacMastery. Until now, it works fantastic, and now we plan to order another line." - Mohamed

Case Studies

Real-life case studies highlight the impact of our machines on production rates, cost savings, and overall efficiency. These success stories demonstrate how our clients have been able to scale their operations and achieve significant improvements in their manufacturing processes.

Market Trends and Future Outlook

The baby diaper market is witnessing significant growth, driven by increasing demand for disposable diapers and advancements in manufacturing technology. Manufacturers are continually seeking ways to improve efficiency, reduce costs, and meet the evolving needs of consumers. Here are some key market trends and future outlooks:

Increasing Demand for Disposable Diapers

The convenience and hygiene benefits of disposable diapers have led to their widespread adoption. Parents prefer disposable diapers for their ease of use, reliability, and comfort for their babies. This growing demand is pushing manufacturers to invest in fully automatic packing machines to keep up with production needs and maintain a competitive advantage.

Focus on Sustainability

Sustainability is becoming a critical factor in the manufacturing industry. Consumers are increasingly concerned about the environmental impact of the products they use, and manufacturers are responding by incorporating eco-friendly materials and practices. Our fully automatic baby diaper packing machines support this shift by being energy-efficient and capable of using biodegradable packaging materials.

Integration of Smart Manufacturing Technologies

The integration of Industry 4.0 technologies, such as the Internet of Things (IoT) and data analytics, is transforming the diaper manufacturing process. These technologies enable real-time monitoring and optimization of production lines, leading to improved efficiency, reduced downtime, and better quality control. Our machines are equipped with smart features that allow manufacturers to leverage these advanced technologies.

Choosing the Right Baby Diaper Packing Machine

Selecting the right packing machine is crucial for maximizing efficiency and ensuring high-quality production. Here are some factors to consider:

Factors to Consider

- Speed and Capacity: Assess the production requirements and choose a machine that can meet the desired output.

- Customization Options: Ensure the machine can be customized to produce various diaper sizes and types.

- Energy Efficiency: Look for machines that offer energy-saving features to reduce operational costs.

- Innovative Features: Consider machines with advanced features like full-servo control, ultrasonic welding, and gusset-making mechanisms.

Expert Advice

Our industry experts recommend conducting a thorough analysis of your production needs and future growth plans before investing in a packing machine. Consider the long-term benefits of automation, including cost savings, improved efficiency, and enhanced product quality. For personalized advice and assistance, visit our contact page.

Conclusion

Investing in fully automatic baby diaper packing machines is a strategic move for manufacturers looking to enhance productivity, reduce costs, and maintain high hygiene standards. At PacMastery, we are committed to providing innovative solutions that empower businesses to achieve their goals. Our state-of-the-art machines, combined with our dedication to customer satisfaction and sustainability, make us the ideal partner for your packaging needs.