Key Takeaways Table

| Question | Answer |

|---|---|

| What is a vertical vacuum packing machine? | Assessing needs, comparing technical specifications, and considering budget and ROI. |

| Key features of vertical vacuum packing machines? | Technical specifications, material compatibility, extended shelf life, efficiency, productivity, and customization options. |

| Benefits of using vertical vacuum packing machines? | Extended shelf life, improved efficiency and productivity, and versatility for various packaging needs. |

| Top models on the market? | MF 60 VACUUM by MF TECNO, Sevana Vertical Vacuum Packing Machine, Utien’s Industrial Vacuum Machines, Hawo HV Range by Valdamark, Eco Vac 420V TB by ISG PACK. |

| How to choose the right machine? | Assessing needs, comparing technical specifications, considering budget and ROI. |

| Expert tips for maximizing use? | Regular maintenance, optimization techniques, and best practices for efficient operation. |

Introduction

At PacMastery, our mission is to revolutionize the packing machinery industry through innovative solutions, unparalleled quality, and relentless dedication to customer satisfaction. We strive to empower businesses around the globe with cutting-edge technology and customized machinery, ensuring efficiency, reliability, and excellence in every packaging process. Committed to sustainability and ethical practices, we are not just building machines; we’re crafting a more efficient, productive, and responsible future in packaging.

What is a Vertical Vacuum Packing Machine?

A vertical vacuum packing machine is a sophisticated device designed to remove air from a package and seal it tightly. This process extends the shelf life of products, preserves their quality, and ensures they remain fresh for longer periods. Unlike horizontal vacuum packing machines, vertical models are particularly suited for packaging larger items or products that need to remain upright during the sealing process.

Key Components

- Vacuum Chamber: Removes air from the package.

- Sealing Bar: Seals the package after the air is removed.

- Control Panel: Allows operators to set parameters such as vacuum time, sealing time, and cooling time.

- Material Compatibility: Works with various packaging materials like polyethylene, polypropylene, and aluminum foil.

Key Features of Vertical Vacuum Packing Machines

Technical Specifications

- Dimensions and Weights: For example, the MF 60 VACUUM can handle packages from 330x400 mm to 630x1080 mm, with weights ranging between 5 and 50 kg.

- Cycle Times and Capacities: Models like the Sevana Vertical Vacuum Packing Machine feature dual chambers, significantly enhancing productivity by allowing more packages to be sealed in less time.

Material Compatibility

Vertical vacuum packing machines are highly versatile, capable of working with a range of materials such as:

- Polyethylene (PE)

- Polypropylene (PP)

- Aluminium Foil

These materials are selected based on the product's requirements for barrier properties, durability, and aesthetic appeal.

Benefits of Using Vertical Vacuum Packing Machines

Extended Shelf Life

One of the primary advantages of using a vertical vacuum packing machine is the significant extension of product shelf life. By removing air (specifically oxygen), these machines prevent oxidation and inhibit the growth of bacteria and mold, ensuring products stay fresh for longer periods.

Efficiency and Productivity

Machines like the Sevana Vertical Vacuum Packing Machine, with its dual chamber and tiltable design, enhance productivity by allowing operators to package more items simultaneously and more efficiently. This not only speeds up the packaging process but also optimizes resource use.

Customization and Versatility

Vertical vacuum packing machines offer numerous customization options, making them suitable for various industries. Features like adjustable vacuum and sealing times, different chamber sizes, and compatibility with multiple packaging materials allow businesses to tailor the machine’s operation to their specific needs.

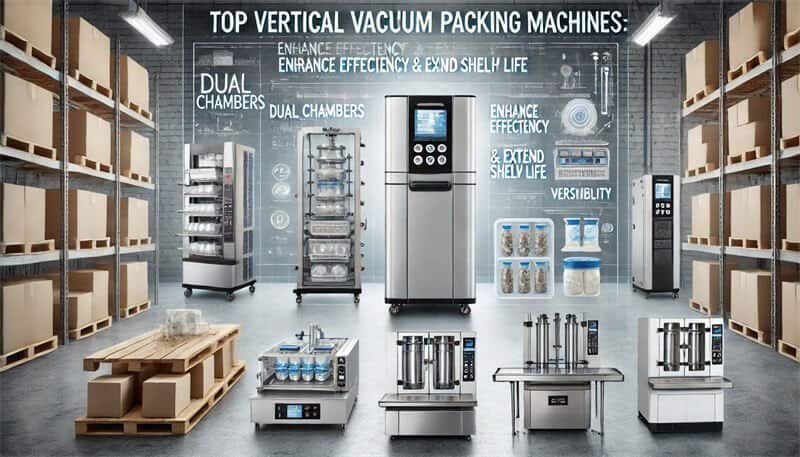

Top Models on the Market

MF 60 VACUUM by MF TECNO

The MF 60 VACUUM is an automatic vertical packaging machine designed for large vacuum-packed formats. Ideal for medium production, it offers format flexibility, a touchscreen operator panel, and a self-diagnosis system. This machine is perfect for industries dealing with pet food, seeds, animal feed, and plastic granules.

Sevana Vertical Vacuum Packing Machine

Known for its dual chambers and tiltable design, the Sevana Vertical Vacuum Packing Machine is engineered for high productivity and flexibility. It features a sensor-based system, microprocessor control, and an emergency stop button, making it a reliable and efficient solution for packaging needs.

Utien’s Industrial Vacuum Machines

Utien offers a range of industrial vacuum packaging machines, from small tabletop models to large industrial versions. These machines are designed to extend the shelf life of food products, maintain their original quality, and improve the aesthetic appearance of packages.

Hawo HV Range by Valdamark

The Hawo HV range includes high-performance vertical vacuum packaging machines suitable for clean room environments. These machines feature impulse heat sealing technology, adjustable settings for vacuum and gas purge, and are made from V2A grade stainless steel.

Eco Vac 420V TB by ISG PACK

The Eco Vac 420V TB offers advanced control panel features, including 10 memories for different working cycles, adjustable vacuum and gas injection times, and a two-digit counter for cycle count. This machine is ideal for businesses looking for customization and efficiency in their packaging processes.

How to Choose the Right Vertical Vacuum Packing Machine

Selecting the ideal vertical vacuum packing machine for your business requires careful consideration of several factors to ensure you make the best investment. Here are key aspects to evaluate:

Assessing Your Needs

- Product Type: Determine the types of products you will be packaging (e.g., food, medical supplies, industrial components).

- Production Volume: Estimate your daily, weekly, or monthly packaging requirements to choose a machine with the appropriate capacity.

- Space Constraints: Consider the physical space available in your facility to ensure the machine fits comfortably and allows for efficient workflow.

Comparing Technical Specifications

- Dimensions and Capacities: Compare the size and capacity of different machines. For example, the MF 60 VACUUM handles larger packages, while the Eco Vac 420V TB offers adjustable settings for various package sizes.

- Cycle Times: Look for machines with faster cycle times if you need to increase productivity, such as the dual-chamber Sevana model.

- Material Compatibility: Ensure the machine can handle the packaging materials you use, like polyethylene, polypropylene, and aluminum foil.

Budget and ROI Considerations

- Initial Cost vs. Long-term Benefits: While some machines might have a higher upfront cost, their efficiency, durability, and low maintenance could offer better long-term value.

- Energy Consumption: Consider energy-efficient models to reduce operational costs.

- Maintenance and Downtime: Choose reliable machines with minimal maintenance needs to avoid costly downtimes.

Expert Tips for Maximizing the Use of Vertical Vacuum Packing Machines

To get the most out of your vertical vacuum packing machine, follow these expert tips:

Regular Maintenance and Care

- Routine Cleaning: Regularly clean the machine, especially the sealing bars and vacuum chamber, to maintain optimal performance.

- Scheduled Inspections: Conduct periodic inspections to check for wear and tear, ensuring all components are in good working condition.

- Replacement of Parts: Replace worn-out parts promptly to prevent breakdowns and maintain efficiency.

Optimization Techniques

- Setting Adjustments: Fine-tune vacuum, sealing, and cooling times based on the product type and packaging material to achieve the best results.

- Operator Training: Ensure operators are well-trained in machine use and maintenance to minimize errors and maximize productivity.

- Utilize Machine Features: Take advantage of advanced features like dual chambers, tiltable designs, and control panels for improved efficiency and flexibility.

Best Practices for Efficient Operation

- Consistent Monitoring: Use the machine’s monitoring systems (like touchscreen panels and self-diagnosis systems) to keep track of operations and address issues promptly.

- Optimize Workflow: Arrange your workspace to ensure a smooth flow of materials to and from the vacuum packing machine, reducing bottlenecks and increasing throughput.

Conclusion

Vertical vacuum packing machines are indispensable for businesses aiming to enhance product shelf life, improve packaging efficiency, and ensure high-quality packaging. By understanding the key features, benefits, and top models on the market, you can make an informed decision that aligns with your business needs. Additionally, following expert tips for maintenance and optimization will help you maximize the machine's potential, ensuring long-term success and productivity.

For more information on our advanced packaging solutions, visit our product page.

Explore more about our commitment to sustainability and ethical practices in packaging at PacMastery. Learn how our granule packing machines and liquid packing machines are setting new standards in the industry.

Continue exploring our comprehensive guides on packaging innovations:

One Response

I wanted to thank you for this wonderful read!! I

absolutely enjoyed every bit of it. I have you savedd aas a favorite to look

aat new stuff you post… https://zeleniymis.COM.Ua/