Key Takeaways Table: Heat Shrink Packing Machines

| Aspect | Details |

|---|---|

| Product Focus | Heat Shrink Packing Machines |

| Purpose | Enhancing efficiency and sustainability in packaging processes |

| Key Features | I-Bar and L-Bar sealers, heat tunnels, combo systems, temperature control, and automation |

| Sustainability | Machines incorporating sustainable practices, reducing environmental impact |

| Technological Advancements | Innovations improving packaging efficiency, safety, and automation |

| Ideal Industries | Suitable for a variety of industries including food, pharmaceutical, and consumer goods |

| Financial Considerations | Various financing options, cost-effectiveness, and return on investment analysis |

| Integration and Training | Tips for integrating into existing production lines, including safety and operational training |

| More Information | PacMastery's Range of Solutions |

Introduction

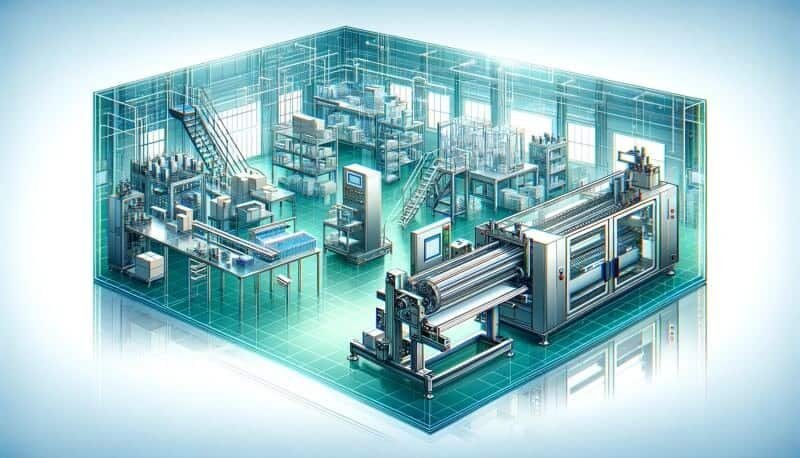

Welcome to the dynamic world of heat shrink packing machines, where PacMastery leads the revolution. At PacMastery, we're not just building machines; we're crafting a more efficient, productive, and responsible future in packaging. Our mission is to revolutionize the packing machinery industry through innovative solutions, unparalleled quality, and relentless dedication to customer satisfaction.

Understanding Heat Shrink Packing Machines

Heat shrink packing machines, the cornerstone of modern packaging technology, serve to efficiently wrap products in a heat-sensitive film. This film shrinks tightly around the item upon heating, offering a secure and aesthetic packaging solution. Key types include:

- I-Bar and L-Bar Sealers: Ideal for wrapping individual items, offering simplicity and efficiency.

- Heat Tunnels: Enhance the shrink wrapping process, ensuring a consistent finish.

- Combo Systems: Combine sealing and shrinking into one streamlined operation.

These machines are essential in industries like food, pharmaceuticals, and consumer goods, ensuring product safety and integrity.

Technological Advancements in Heat Shrink Machines

The technological evolution in shrink wrapping machinery has been remarkable. At PacMastery, we stay at the forefront, integrating:

- Automated Temperature Control: Ensuring consistent quality.

- Efficient Design: Maximizing output while minimizing energy consumption.

- User-friendly Interfaces: Simplifying operation and maintenance.

Our advanced machinery exemplifies these innovations, enhancing both productivity and reliability.

Sustainability in Packaging - A Necessity, Not a Choice

Sustainability isn’t just a trend; it's an imperative. Our heat shrink machines are designed with the environment in mind, reducing waste and energy use. We draw inspiration from industry leaders and commit to:

- Eco-Friendly Materials: Using recyclable and biodegradable films.

- Energy Efficiency: Minimizing the carbon footprint of our machines.

- Long-Term Durability: Reducing the need for frequent replacements.

Explore how we integrate sustainability into every aspect of our operations at PacMastery.

Product Spotlight - High-Performance Heat Shrink Machines

PacMastery prides itself on offering a range of top-tier heat shrink machines. Each model is carefully designed to meet diverse business needs, ensuring efficiency and quality. Here are some standout features:

- SEAL 'N SHRINK: Renowned for its capacity to handle high-volume packaging with impeccable seal quality.

- SHRINKMASTER: Ideal for businesses seeking precision and speed in their packaging processes.

To explore our complete product line and understand the unique benefits of each machine, visit our product page.

Choosing the Right Heat Shrink Packing Partner

Selecting a heat shrink machine supplier is crucial for ensuring long-term success in your packaging operations. Here's what to look for:

- Quality and Reliability: Machines should be durable and dependable, minimizing downtime.

- Customer Support: Look for suppliers offering comprehensive support, from installation to maintenance.

- Tailored Solutions: Your business is unique; your packaging solutions should be too. PacMastery offers customized machinery tailored to specific industry needs.

Financial Aspects and Purchasing Plans

Investing in a heat shrink packing machine is a significant decision. At PacMastery, we provide various financing options to make this technology accessible. Factors to consider include:

- Cost-Effectiveness: Assessing the long-term savings in labor and materials.

- Return on Investment: Calculating how the machine will contribute to increased productivity and reduced waste.

For detailed financial considerations and purchasing plans, delve into our comprehensive guide.

Integrating Heat Shrink Packing Solutions into Your Business

Integrating a new machine into your production line should be seamless. We offer:

- On-site Training: Ensuring your team is well-equipped to operate the machinery efficiently.

- Safety Protocols: Prioritizing the safety of your staff during machine operation.

- Custom Integration Plans: Tailoring the setup to fit your existing production line seamlessly.

Discover more about integrating these solutions at PacMastery.

Future Trends in Heat Shrink Packing

The future of heat shrink packing is bright with potential advancements like:

- AI and Machine Learning: For smarter, more efficient operations.

- Sustainable Innovations: Continuing to reduce environmental impact.

- Advanced Material Use: Exploring new, eco-friendly shrink film options.

Stay updated with the latest trends at PacMastery's blog.

Conclusion

The world of heat shrink packing machines is evolving rapidly, with technology and sustainability at its core. At PacMastery, we are committed to providing cutting-edge solutions that meet the dual goals of efficiency and environmental responsibility. Embracing these innovative solutions is not just a smart business decision; it's a step towards a more sustainable future.