Key Takeaways

| Aspect | Details |

|---|---|

| Types of Machines | Improved efficiency, product safety, cost reduction, and enhanced sustainability. |

| Primary Benefits | Improved efficiency, product safety, cost reduction, enhanced sustainability. |

| Key Features | Automation level, speed, compatibility with materials, maintenance ease, compliance with standards. |

| Popular Applications | Food preservation, ready meals, liquids, powders, snacks, and industrial-scale packaging solutions. |

| Emerging Trends | AI and IoT integration, eco-friendly materials, and compact machines for smaller businesses. |

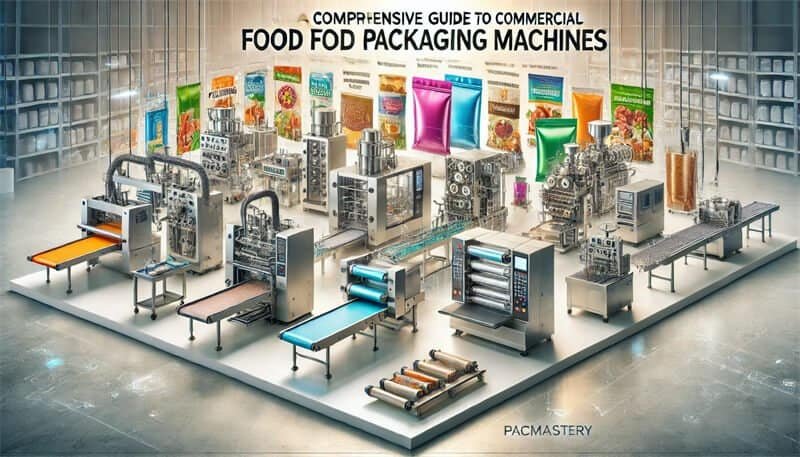

At PacMastery, our mission is to revolutionize the packaging industry by empowering businesses with cutting-edge machinery. Commercial food packaging machines are a cornerstone of modern food production, offering unmatched efficiency, safety, and quality assurance. This guide explores the types, benefits, and innovations of these machines, helping you make informed decisions for your business.

Types of Commercial Food Packaging Machines

1. Vacuum Packaging Machines

Vacuum packaging machines are essential for preserving food by removing air from the packaging. This process:

- Extends shelf life by preventing oxidation and bacterial growth.

- Is widely used for perishable items like meats, cheeses, and vegetables.

- Offers flexible options, including tabletop and industrial-grade machines.

Explore our advanced vacuum solutions here: Vacuum Packaging Machines.

2. Filling and Sealing Machines

Ideal for liquids, powders, and granules, filling and sealing machines streamline the packaging process. These machines:

- Come in automatic and semi-automatic models.

- Ensure precise filling, reducing waste and spillage.

- Are commonly used for products like sauces, beverages, and powdered foods.

Discover innovative solutions for liquids here: Advanced Liquid Packaging Solutions.

3. Thermoforming Packaging Machines

These machines mold plastic films into custom shapes, ideal for food trays and vacuum-sealed products. Key benefits include:

- High-speed packaging for ready-to-eat meals.

- Compatibility with eco-friendly materials.

- Enhanced product presentation and durability.

Benefits of Using Commercial Food Packaging Machines

Investing in commercial food packaging machines delivers numerous advantages:

- Improved Efficiency

- Automates repetitive tasks, reducing labor costs.

- Speeds up production lines, meeting high-demand needs.

- Product Safety and Compliance

- Ensures hygienic packaging that meets industry standards.

- Protects food from contamination during handling and storage.

- Cost-Effective Operations

- Reduces waste through precise filling and sealing mechanisms.

- Lowers long-term expenses by minimizing manual intervention.

- Sustainability

- Supports the use of biodegradable and recyclable materials.

- Reduces environmental impact with energy-efficient designs.

Key Features to Consider

When selecting a food packaging machine, evaluate these crucial features:

- Automation Level: Decide between manual, semi-automatic, or fully automatic based on your production scale.

- Capacity and Speed: Choose a machine that aligns with your output requirements.

- Material Compatibility: Ensure compatibility with various packaging materials, such as plastic, paper, and foil.

- Ease of Maintenance: Look for machines with user-friendly designs and minimal downtime.

- Compliance Standards: Opt for machines certified for food safety and industry regulations.

Learn more about tailored solutions here: Selecting the Right Food Packaging Machinery.

Emerging Trends and Innovations

As technology evolves, commercial food packaging machines are integrating advanced features to meet modern needs:

- AI and IoT Integration: Enables predictive maintenance and real-time monitoring for increased reliability.

- Eco-Friendly Solutions: Supports sustainable practices with biodegradable materials and energy-efficient operations.

- Compact Designs: Caters to small businesses seeking space-efficient and cost-effective machinery.

Comparative Analysis of Popular Food Packaging Machines

Selecting the right machine requires understanding the features and benefits of available options. Below is a comparison of popular packaging machines to help you make an informed decision.

| Machine Type | Best For | Key Features | Cost Range |

|---|---|---|---|

| Vacuum Packaging Machines | Perishable goods (meats, cheeses, etc.) | Removes air, extends shelf life, compact size | $1,000 - $15,000 |

| Filling & Sealing Machines | Liquids, powders, granules | Precise filling, spillage prevention | $5,000 - $30,000 |

| Thermoforming Machines | Ready meals, industrial packaging | Custom molds, eco-material compatibility | $20,000 - $100,000 |

| Pouch Packaging Machines | Snacks, beverages, sauces | Flexible packaging options, branding-friendly | $10,000 - $50,000 |

| End-of-Line Machines | Bulk packaging and transportation | Palletizing, case packing, stretch wrapping | $25,000 - $150,000 |

Our tailored solutions make choosing the right machine easier: Explore Packaging Machines.

Expert Advice on Selecting the Right Machine

Choosing the ideal food packaging machine depends on several factors. Consider these tips from industry experts:

- Assess Your Business Needs

- Identify the type of product you’re packaging (e.g., liquid, powder, solid).

- Evaluate your production volume and frequency.

- Plan for Future Growth

- Opt for machines that can scale with your business.

- Prioritize automation to accommodate increased demand.

- Focus on Quality and Compliance

- Ensure machines meet safety and hygiene standards.

- Choose certified models for specific industries, such as pharmaceuticals or food service.

- Seek Expert Consultation

- Consult with packaging specialists to tailor solutions to your needs.

- Work with trusted manufacturers for reliable support and maintenance.

Get started with expert insights here: Innovative Food Packaging Solutions.

Real-World Case Studies

Case Study 1: Scaling a Small Business

A small artisanal food company invested in semi-automatic pouch packaging machines to reduce manual labor and improve consistency. As a result:

- Productivity increased by 50%.

- Packaging quality met industry standards, leading to broader market reach.

Case Study 2: Large-Scale Automation

A global snack manufacturer implemented a fully automated thermoforming system. Key outcomes included:

- A 30% reduction in production costs.

- Enhanced sustainability by switching to recyclable materials.

These examples highlight how the right packaging machines can transform businesses. Discover more transformative solutions here: Custom Packaging Machines.

Conclusion

Commercial food packaging machines are more than tools; they are strategic investments that elevate efficiency, enhance product safety, and contribute to business growth. From vacuum packaging to advanced automation, each solution plays a critical role in modern food production.

At PacMastery, we are committed to revolutionizing the packaging industry with innovative, customized solutions. Whether you're a small business or a large enterprise, our expertise and cutting-edge machinery will help you optimize your packaging process for success.

Explore our comprehensive range of solutions to take your packaging to the next level: Visit PacMastery.